Product

ontwikkeling

ontwikkeling

Het Innovatiecentrum van Bolidt vormt het innovatieve hart van ons bedrijf. Hier wordt voortdurend gewerkt aan nieuwe systemen voor bestaande en nieuwe toepassingen. We verhogen de isolatiewaarden, verminderen geluidoverlast en zorgen ervoor, dat de systemen steeds functioneler en duurzamer worden, met behoud van alle esthetische mogelijkheden.

Daarbij besteden we ook veel aandacht aan de eenvoud van verwerking van onze systemen. Zo worden faalkosten in de applicatie, en daaraan verbonden onnodig afval en onnodig verbruik van grondstoffen en energie, bij voorbaat vermeden.

Daarbij besteden we ook veel aandacht aan de eenvoud van verwerking van onze systemen. Zo worden faalkosten in de applicatie, en daaraan verbonden onnodig afval en onnodig verbruik van grondstoffen en energie, bij voorbaat vermeden.

Product

ontwikkeling

ontwikkeling

Het Innovatiecentrum van Bolidt vormt het innovatieve hart van ons bedrijf. Hier wordt voortdurend gewerkt aan nieuwe systemen voor bestaande en nieuwe toepassingen. We verhogen de isolatiewaarden, verminderen geluidoverlast en zorgen ervoor, dat de systemen steeds functioneler en duurzamer worden, met behoud van alle esthetische mogelijkheden.

Daarbij besteden we ook veel aandacht aan de eenvoud van verwerking van onze systemen. Zo worden faalkosten in de applicatie, en daaraan verbonden onnodig afval en onnodig verbruik van grondstoffen en energie, bij voorbaat vermeden.

Daarbij besteden we ook veel aandacht aan de eenvoud van verwerking van onze systemen. Zo worden faalkosten in de applicatie, en daaraan verbonden onnodig afval en onnodig verbruik van grondstoffen en energie, bij voorbaat vermeden.

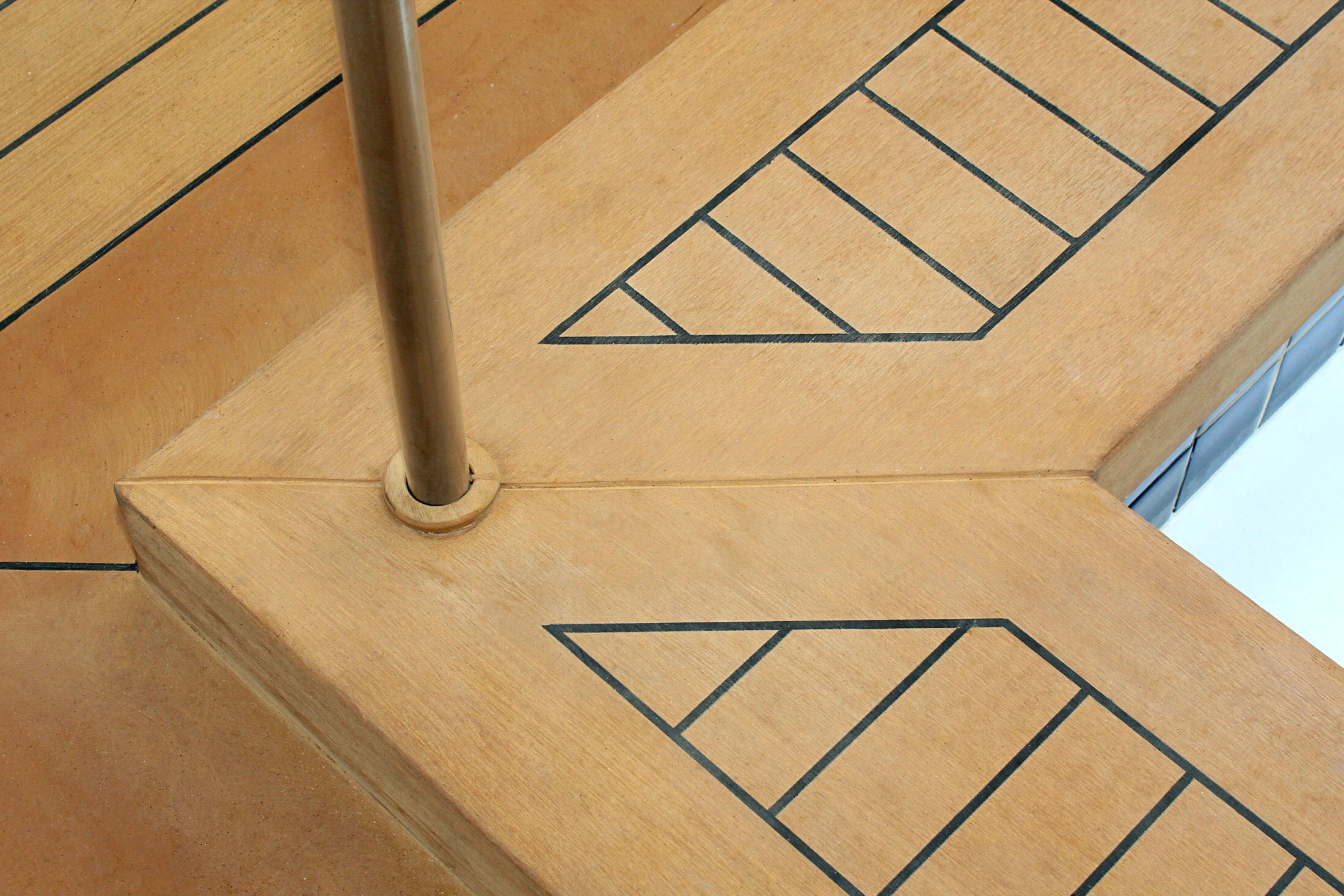

Prefab

Ook zijn er tal van ontwikkelingen bij Bolidt op het gebied van prefab productie, waarbij het volledig uitgeharde eindproduct wordt gemaakt in Hendrik-Ido-Ambacht. Deze productontwikkelingen zorgen ervoor dat de toch al geringe hoeveelheid afval die Bolidt genereert, tot nul wordt gereduceerd.

Zelfs eventuele zaagresten worden gebruikt als monstermateriaal. Binnen de prefab systemen wordt het bovendien mogelijk om direct isolatiemateriaal op te nemen. Met name in de scheepsbouw levert dit een enorme besparing in brandstofverbruik op; een geïsoleerd stalen dek betekent dat er minder energie nodig is voor verwarming- en aircosystemen.

De prefab systemen van Bolidt leiden tot minder afval, minder energieverbruik en minder CO2- uitstoot.

Bolidt ontwikkelt prefab systemen voor scheepsdekken. Uitgangspunt hierbij is, dat het composiet dek als plaatmateriaal op maat wordt gemaakt in onze fabriek in Hendrik-Ido-Ambacht.

Naast het feit dat hierdoor productafval tot nul wordt gereduceerd, betekent prefab productie ook dat applicatie en groot onderhoud van een scheepsdek kan worden gedaan door minder mensen in minder tijd. Bovendien zijn de applicatie en onderhoud van een prefab dek eenvoudiger, waardoor een steeds groter deel van de werkzaamheden kan worden uitgevoerd door lokale krachten.

Gezien het feit dat schepen zich bevinden over de hele wereld, betekent dit een aanzienlijke reductie van reisafstanden door de applicatiespecialisten van Bolidt. En minder reizen veroorzaakt minder CO2-uitstoot.